Topology Standardization of chassis-mounted components of commercial vehicles

Project completed - Contact: ftm(at)ftm.mw.tum.de

The layouts of chassis-mounted components in commercial vehicles, consisting of components such as fuel tank, battery box or exhaust system, are subject to a portfolio-wide high variance. Depending on the truck bodywork, there must be some installation space available, which must be taken into account and provided by the commercial vehicle manufacturer.

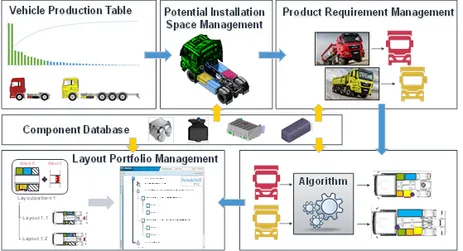

As part of the project, a software-based toolchain has been developed that queries and documents in a first step all the requirements for standardization of the layouts. After the detailed requirement definition, all technically valid package alternatives are generated with the help of an algorithm. Subsequently, the tool chain enables a cross-portfolio solution search, which alternative should be used to realize a minimal component and position variance in the overall portfolio.